Application areas

Rare earth industry

Rare earth elements

The development and application of rare earths mainly involves three steps: ore selection, smelting, and purification. Rare earths are extracted through separation and processing, and the extracted rare earth ores require smelting and separation processes to obtain pure or mixed rare earth metals and their oxides. This step is crucial for the purity and quality of rare earth elements.

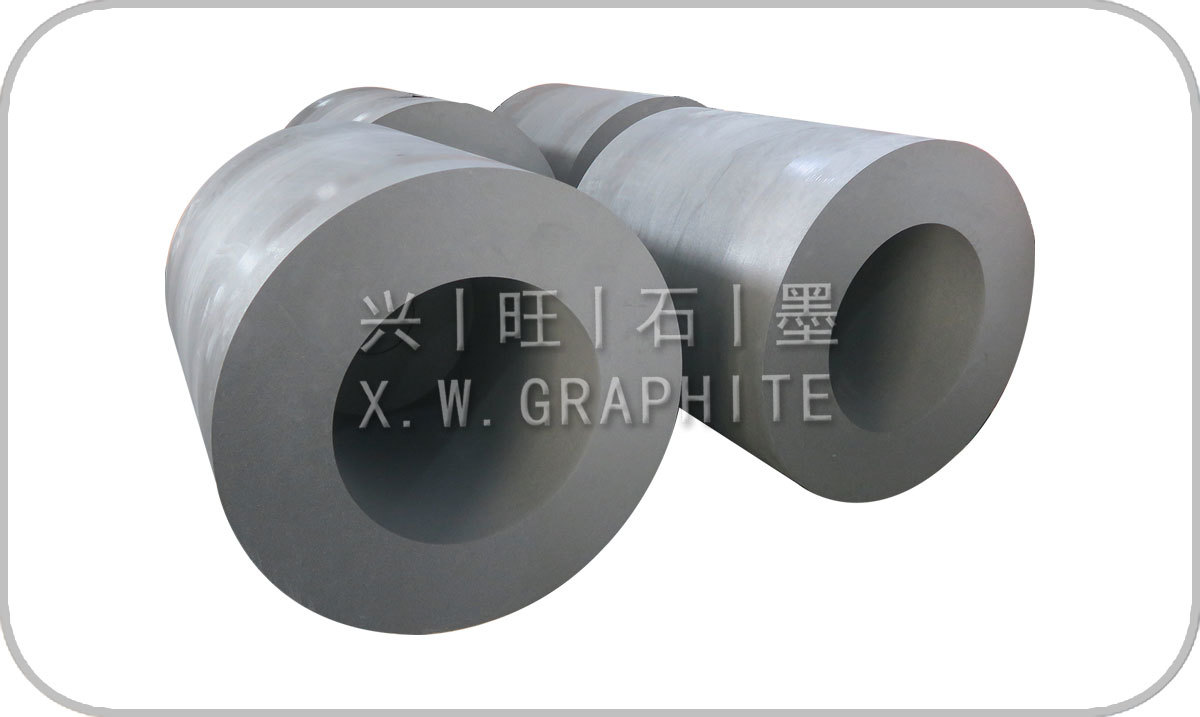

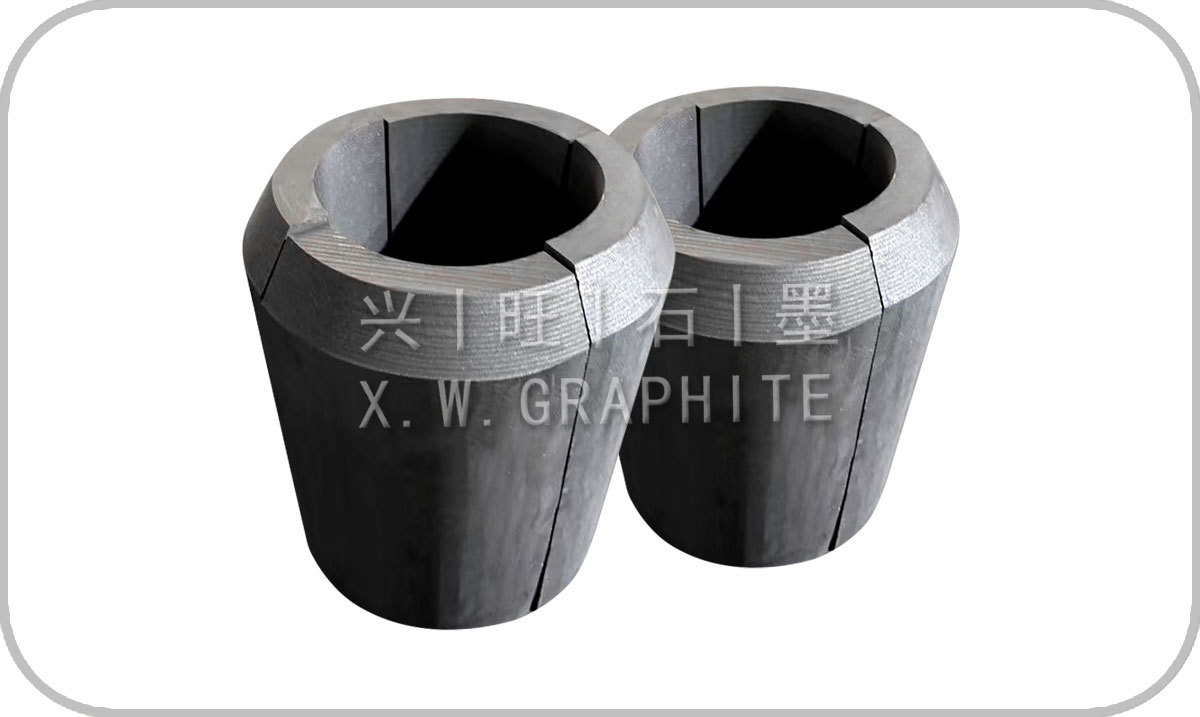

Graphite flow troughs used in rare earth smeltingCharacteristics:

1. High temperature stability, able to withstand the high temperature environment during the rare earth smelting process

2. Excellent thermal conductivity, capable of quickly and evenly dispersing the heat generated during the smelting process

3. Good corrosion resistance, graphite crucibles can prevent corrosion and contamination during the rare earth smelting process

4. High purity, to ensure the cleanliness during the smelting process and the quality of rare earth products

5. Good thermal expansion properties, beneficial for temperature control in rare earth smelting

6. Easy to operate, graphite crucibles have a long service life, reducing the production costs of rare earth smelting

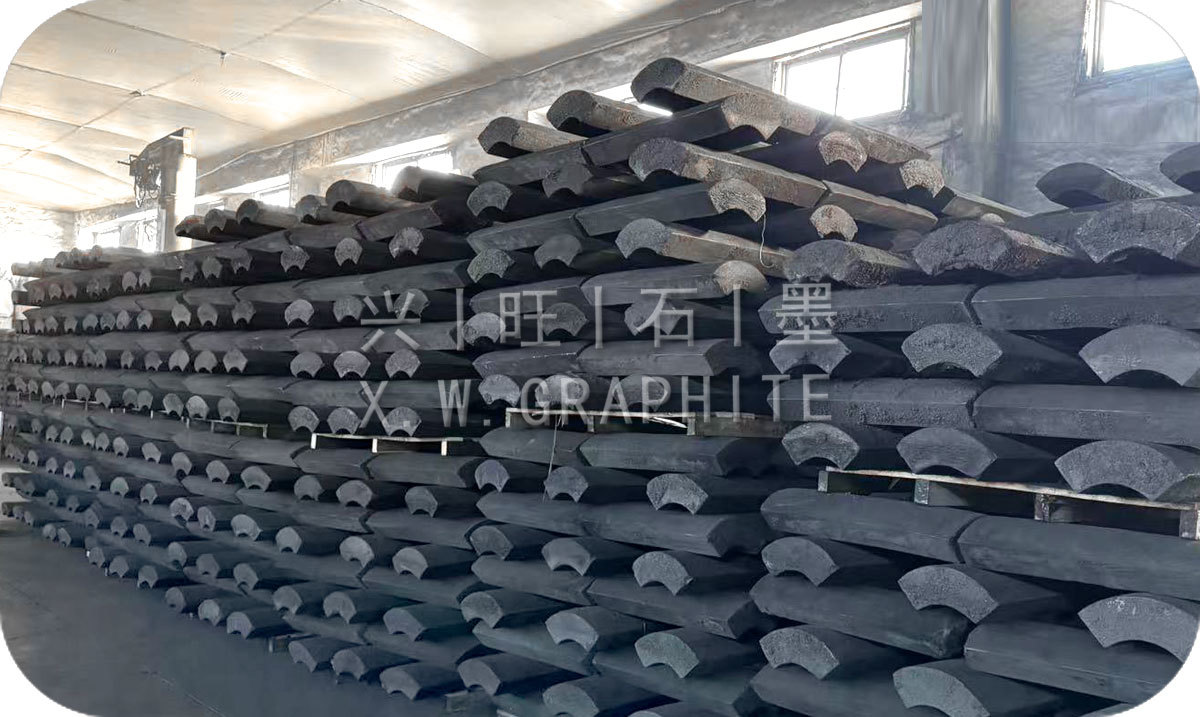

Graphite anodes

In the rare earth industry, graphite anode plates are mainly used in the electrolysis of rare earth metal oxides and the purification of metals. In rare earth smelting, graphite anode plates participate in chemical reactions as anodes, and their excellent conductivity and high-temperature resistance ensure the efficient and stable operation of the smelting process. They are key components in rare earth smelting.

Rapid development of the rare earth industry

With the rapid development of the rare earth industry, the demand for special graphite is also continuously increasing. The application of graphite products in rare earth smelting not only improves production efficiency but also reduces energy consumption and costs, promoting the sustainable development of the rare earth industry.