Application areas

New energy battery industry

The Core Role of Graphite Crucibles in Lithium-Ion Battery Production

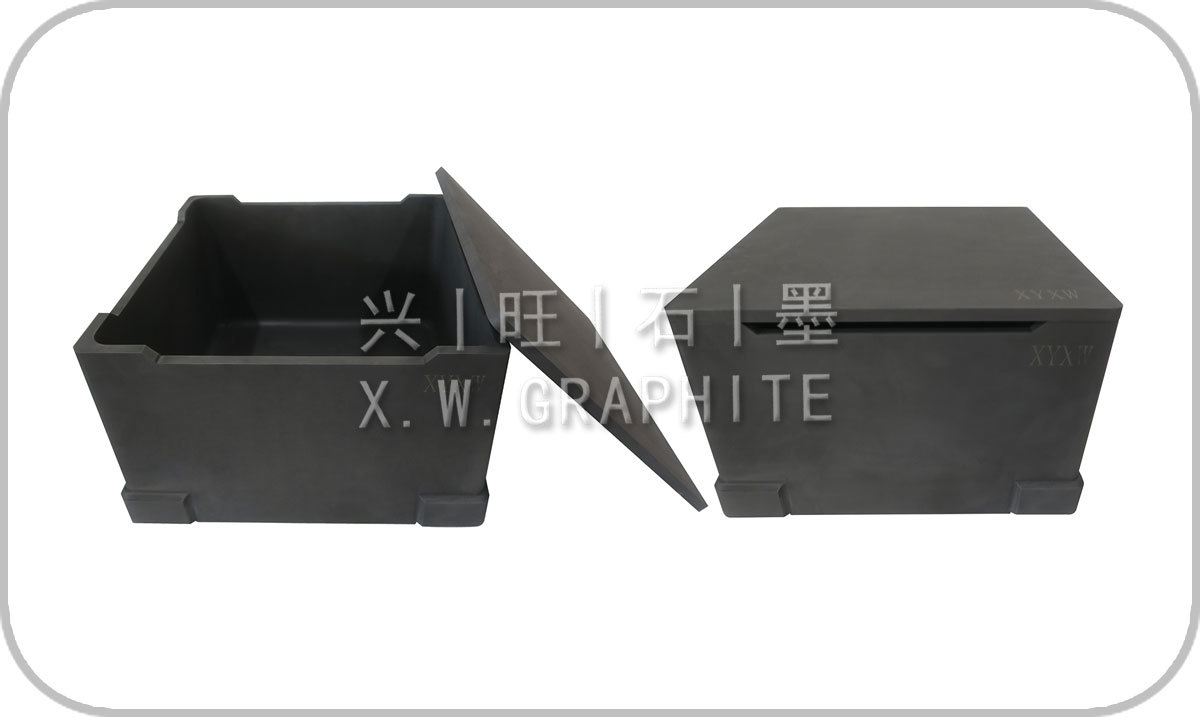

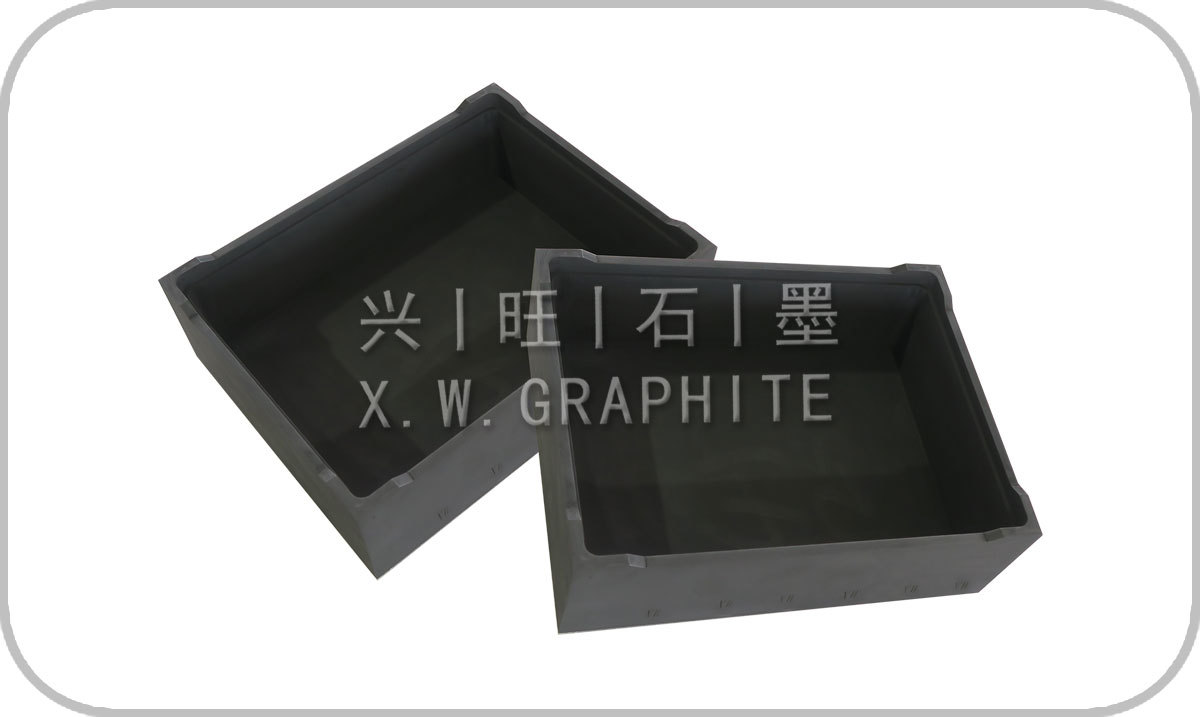

Sintering of Cathode Materials: Graphite crucibles, due to their high-temperature resistance and low thermal conductivity, have become an ideal choice in the sintering process of battery materials. They play a key role, especially in the sintering process of lithium iron phosphate cathode materials.

Avoiding Material Loss and Contamination: Lithium battery-specific crucibles must possess excellent corrosion resistance, fire resistance, and thermal shock resistance. This not only effectively prevents material loss and contamination during the synthesis process of cathode materials but also improves production efficiency and facilitates manual operation.

The Importance of Graphite in the New Energy Industry

● Resource Scarcity: Global graphite resources are limited, and countries are taking measures to restrict graphite exports to protect this rare material. As one of the largest graphite producers in the world, China's export restrictions have a significant impact on the development of the global new energy industry.

● Market Demand: In the new energy battery industry, the consumption of graphite accounts for 50%, highlighting its important position in the new energy field.

● Technological Advancements: With the progress of technology, the application of graphite in the new energy industry will become more extensive and in-depth, with greater potential in high-performance batteries and energy storage devices.

● Market Prospects: As one of the largest graphite producing countries globally, China's graphite output accounts for more than two-thirds of the world's total output, providing ample raw material supply for the development of the lithium battery graphite crucible market.

The Market Prospects for Graphite Crucibles are Very Promising

With the growing global demand for clean energy and new energy vehicles, the market prospects for graphite crucibles are very promising.