Application areas

SIC Semiconductor

Special graphite for the semiconductor industry

Our materials are suitable for various types of crystal growth furnaces. We also provide bases for silicon epitaxy and MOCVD. We process graphite components through machining and other processes to meet the specific application requirements. Comprehensive quality control ensures that our customers receive high-quality, traceable products.

Crystal growth

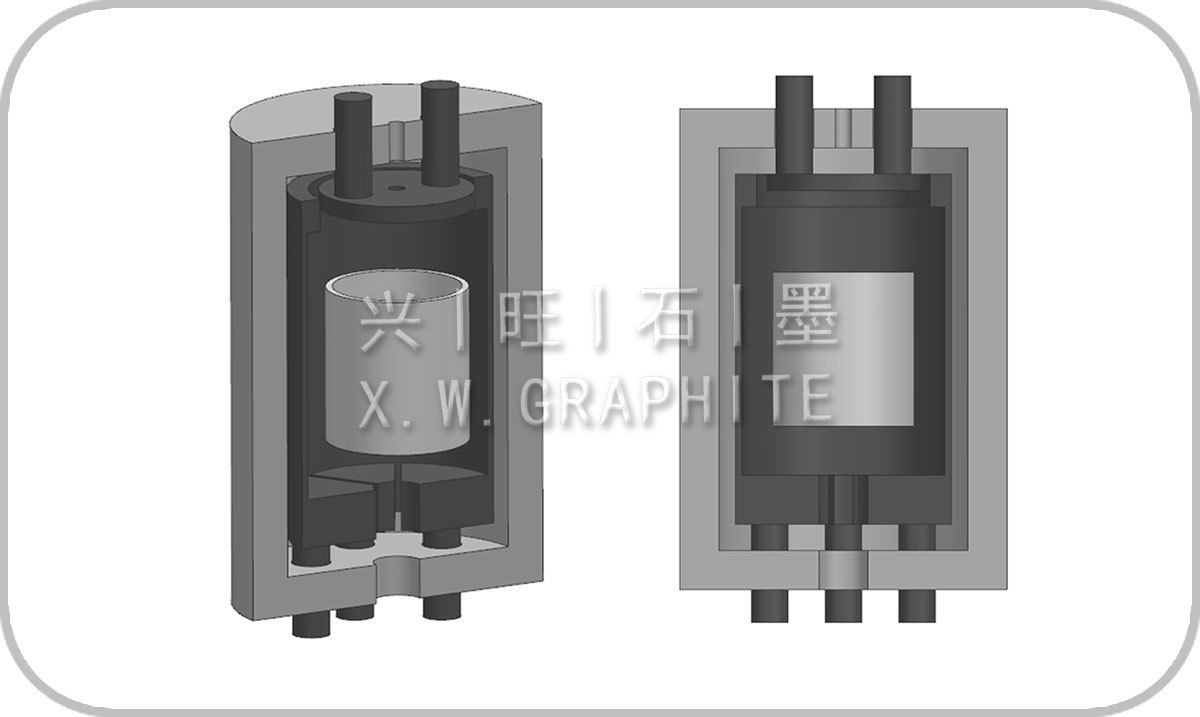

For graphite components used in the semiconductor production process, high purity is a key requirement. The impurity content should be kept below five parts per million. In a vacuum environment, the vacuum chamber contains the main graphite heater, main graphite electrode, graphite crucible, and graphite insulation carbon, among others.

● Heater

● Crucible

● Graphite insulation tube

● Graphite electrode

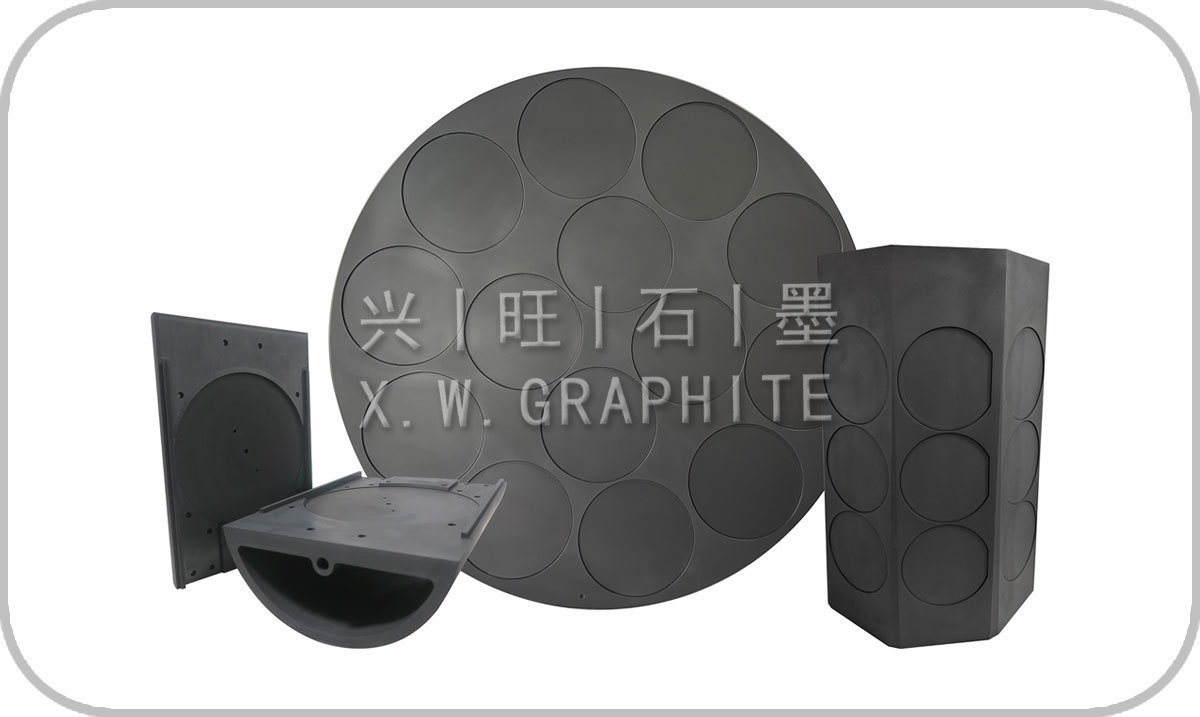

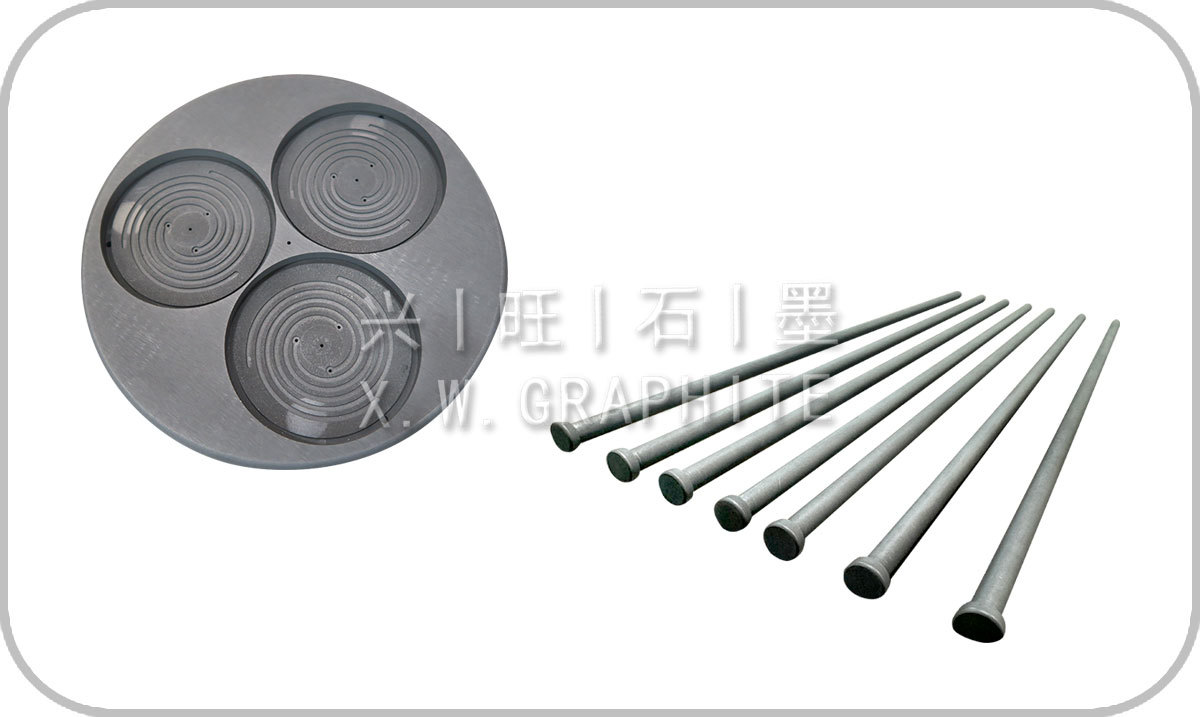

Suitable for epitaxial growth processes and materials

The production of electronic devices requires several steps. One important process is silicon epitaxy. The performance and quality of the base play a crucial role in the quality of the wafer epitaxial layer.

All our bases are made of high-strength isostatic graphite products. Comprehensive quality control ensures that our customers always receive high-quality, fully traceable products. We continuously innovate, breaking through technical barriers and constantly optimizing to create practical solutions that provide real value.

● Accuracy ±0.003

● Purity below 1 PPM

● Silicon carbide layer

Manufacturing semiconductor devices

Graphite can also be used to manufacture semiconductor devices such as diodes, transistors, and integrated circuits. Graphite has high electrical conductivity and thermal conductivity, making it suitable as a substrate material for semiconductor devices. Additionally, graphite can be used to manufacture components such as electrodes and heat sinks.