Application areas

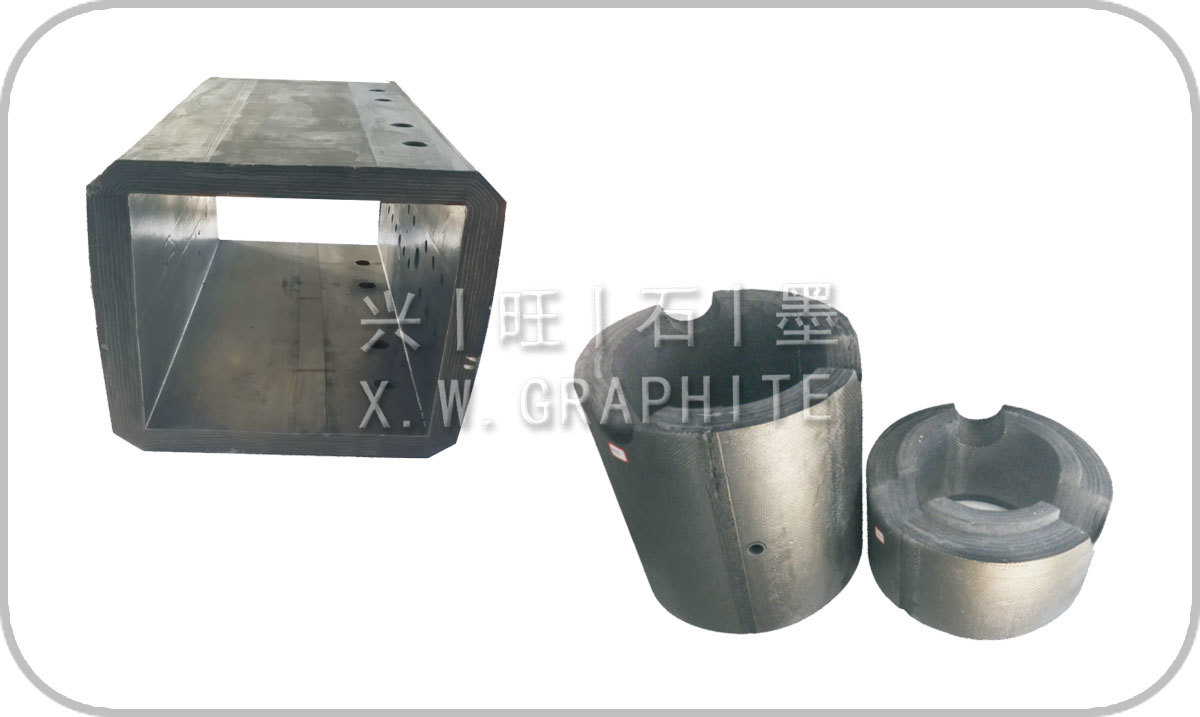

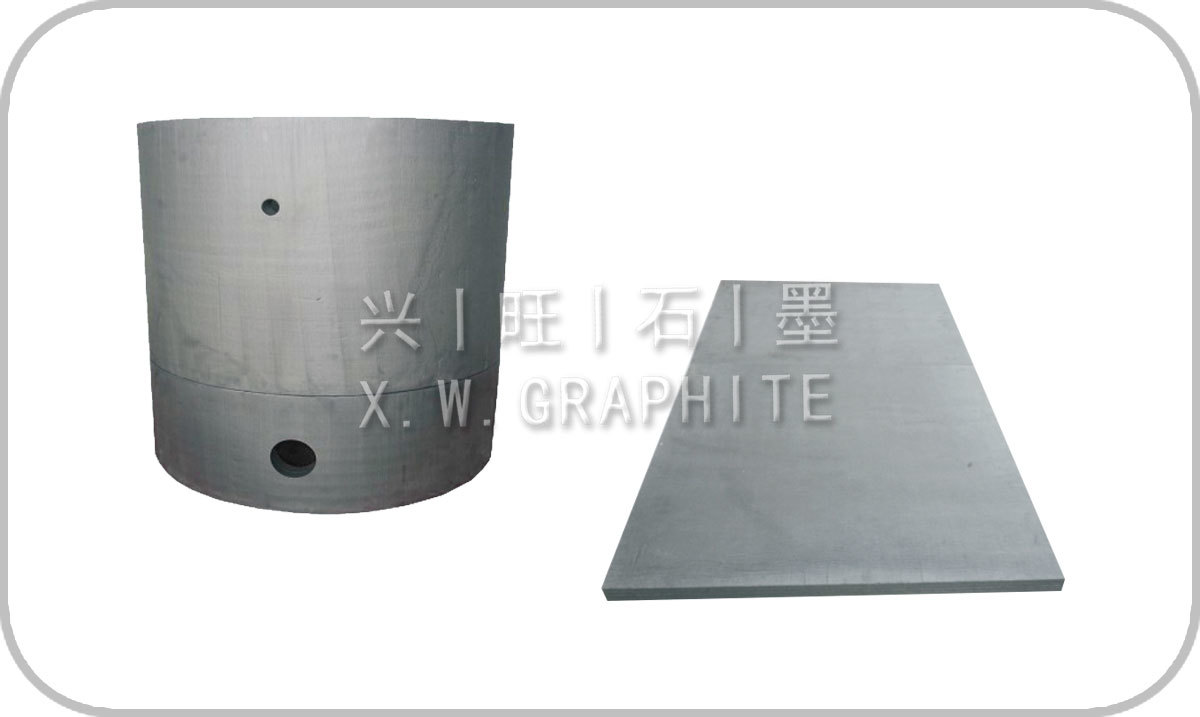

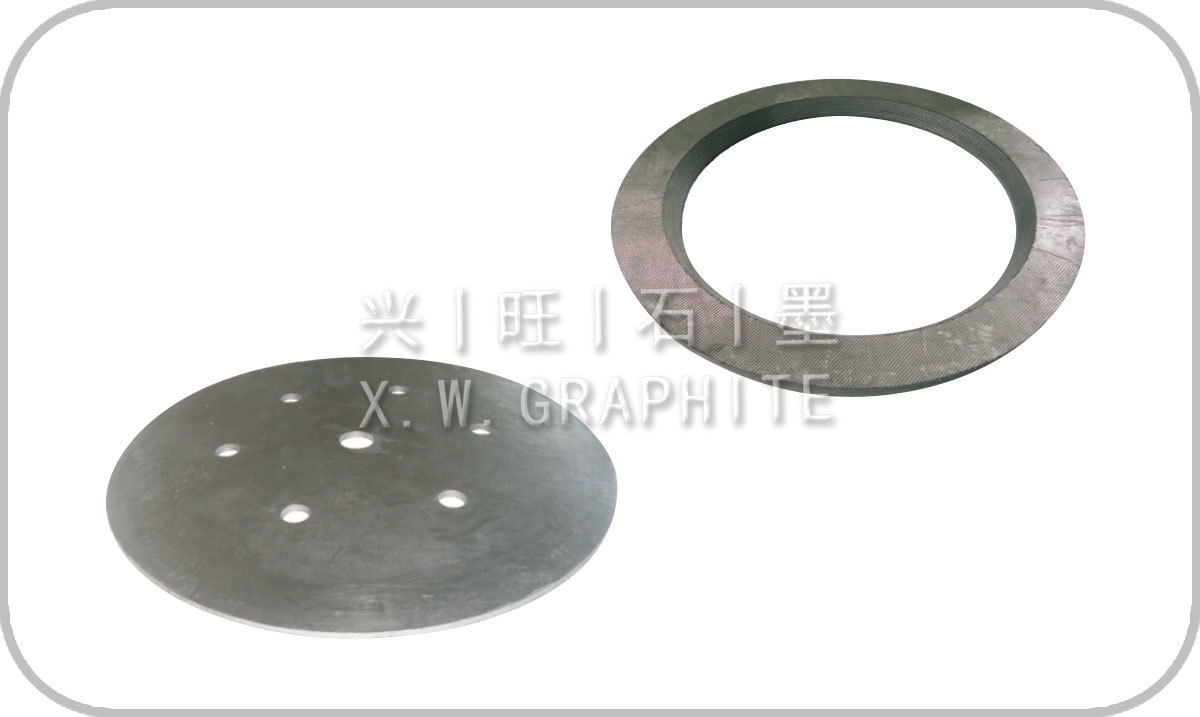

Insulation material

Graphite hard felt is a high-performance insulation material made from graphite fibers and carbon-based materials.

Main Features

High Temperature Resistance: Graphite hard felt can be used in high-temperature environments above 2000°C, with some products remaining stable even at extreme temperatures of 2800°C.

Thermal Insulation: Graphite hard felt maintains good thermal insulation performance at high temperatures, effectively preventing heat transfer.

Easy Assembly: Graphite hard felt has good processability and plasticity, making it easy to assemble and shape.

Application Fields

Graphite hard felt is widely used as an insulation layer in high-temperature equipment such as industrial furnaces, vacuum furnaces, and single crystal furnaces.

It is also used in fields requiring high-temperature insulation and corrosion resistance, such as metallurgy, chemical industry, and glass industries.

Difference Between Hard Felt and Soft Felt

Graphite hard felt has higher strength and hardness, suitable for applications requiring higher pressure and rigidity.

Graphite soft felt has better water absorption and softness, suitable for applications requiring better adsorption and flexibility.

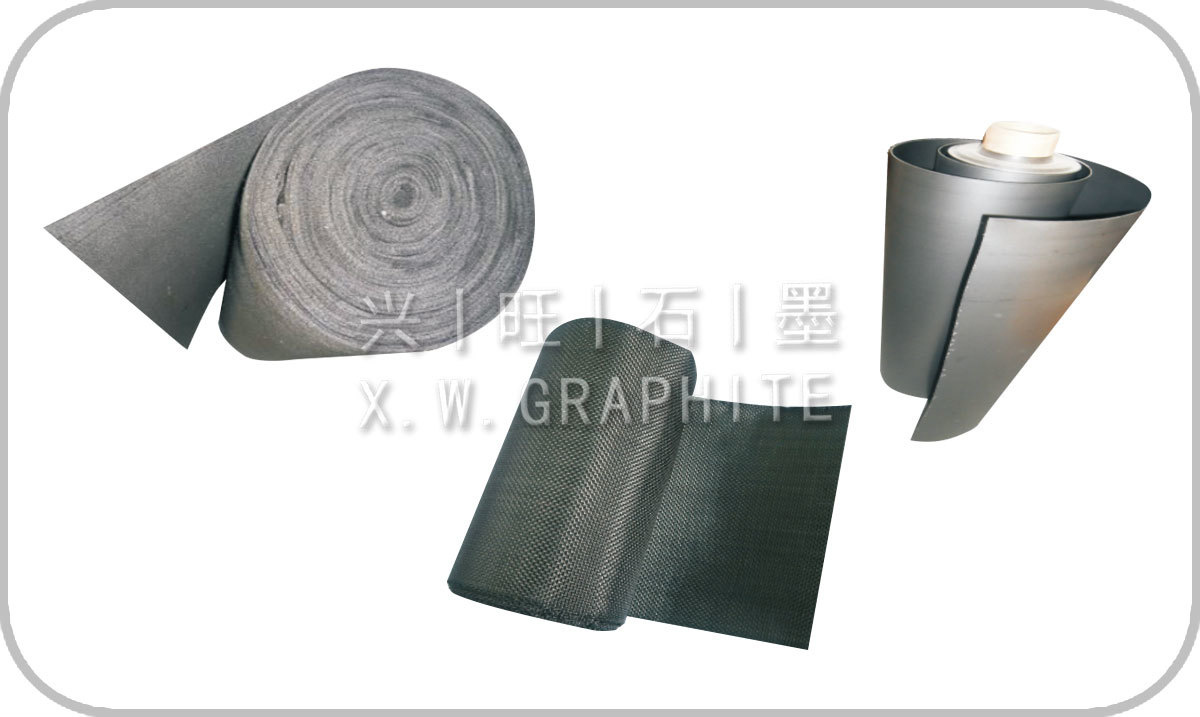

Graphite Soft Felt

Graphite soft felt is known for its soft and porous texture, possessing high thermal conductivity and good adsorption performance.

This material remains stable in high-temperature environments, effectively transferring heat and improving the thermal efficiency of equipment, while its flexibility allows it to easily adapt to various irregular shapes of equipment surfaces, ensuring a tight fit and seal.

In fields such as aerospace, electronic device heat dissipation, chemical corrosion prevention, and building insulation, graphite soft felt plays an irreplaceable role, providing solid support for safe operation in high-temperature environments.